Lean Six Sigma is a synergized managerial concept of Lean and Six Sigma. In the early 2000s Six Sigma principles expanded into other sectors of the economy, such as healthcare, finance, and supply chains.

SIX SIGMA BELTS MEANING HOW TO

It was developed as a guide for managers of manufacturing plants on how to combine lean manufacturing and Six Sigma to improve quality and cycle time in the plant. The first concept of Lean Six Sigma was created in Chuck Mills, Barbara Wheat, and Mike Carnell's 2001 book, Leaning into Six Sigma: The Path to Integration of Lean Enterprise and Six Sigma. While Lean Six Sigma developed as a specific process of Six Sigma, it also incorporates ideas from lean manufacturing, which was developed as a part of the Toyota Production System in the 1950s. A few years later, General Electric's Jack Welch consulted Bossidy and implemented Six Sigma at the conglomerate.ĭuring the 2000s, Lean Six Sigma forked from Six Sigma and became its own unique process.

In the 1990s, Allied Signal hired Larry Bossidy and introduced Six Sigma in heavy manufacturing. Six Sigma was developed within Motorola to compete with the kaizen (or lean manufacturing) business model in Japan. Lean Six Sigma's predecessor, Six Sigma, originated from the Motorola company in the United States in 1986. It combines Lean Management and Six Sigma to increase the velocity of value creation in business processes. Lean Six Sigma is a process improvement approach that uses a collaborative team effort to improve performance by systematically removing operational waste and reducing process variation.

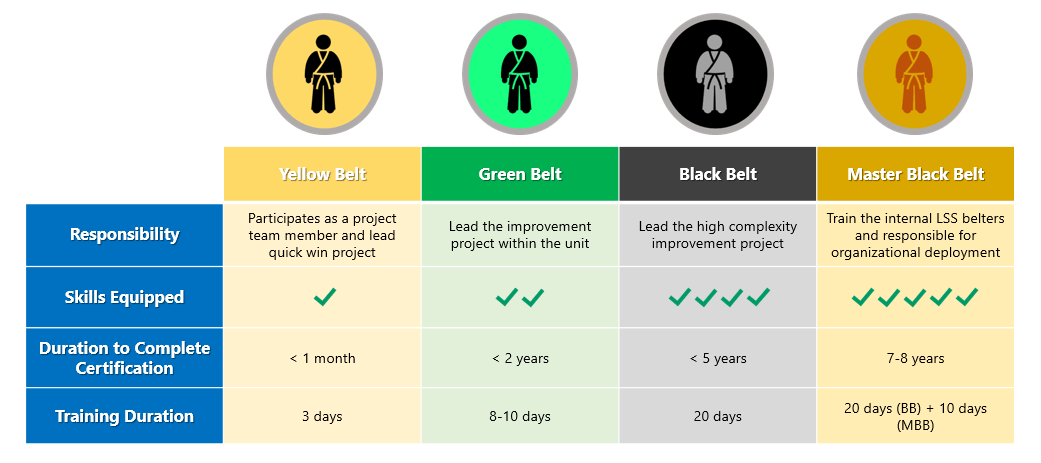

Yellow Belt certification emphasizes the Define-Measure-Control phases and leaves out the technical content covered in the Analyze and Improve phases. You want to understand all aspects of all phases of the Define-Measure–Analyze-Improve-Control (DMAIC) cycle.Unlike White and Yellow Belts, Green Belts regularly lead projects of all sizes and assume a greater level of responsibility when working as a member of a team.

0 kommentar(er)

0 kommentar(er)